Keeping your circular saw blades clean and sharp is essential for accurate cuts, enhanced safety, and longer blade life. Whether you use your saw for cutting lumber, plywood, or other materials, a well-maintained blade reduces tear-out, keeps the motor from overworking, and prevents heat-related damage. In just a few simple steps, you can restore your blades’ cutting efficiency and protect your investment. If you’re looking for specialized tools, consider a circular saw blade cleaning kit to make the process even smoother.

Why Proper Circular Saw Blade Maintenance Matters

A dull or dirty saw blade forces your saw to work harder, increases wear on the motor, and risks binding or kickback. Regular maintenance delivers three key benefits:

- Improved Cutting Quality: A sharp blade produces cleaner cuts with minimal splintering or burn marks, which is critical for finish carpentry or cabinetry.

- Enhanced Safety: Dirt, pitch, and resin buildup can cause the blade to kick back or stall, endangering the operator. Clean blades reduce these hazards.

- Extended Blade and Tool Life: Maintenance reduces friction, heat buildup, and vibration, lowering motor stress and preventing premature blade warping.

Even professional woodworkers incorporate regular blade maintenance into their workflow, much like they follow guides such as Garden Shears Maintenance: Ultimate Guide to Cleaning, Sharpening, and Storage to keep all their tools in peak condition.

Tools and Supplies Needed

Gather these essentials before you begin your blade maintenance session:

- Safety Gear: Wear protective gloves and safety glasses to guard against sharp teeth and cleaning solvents.

- Cleaning Brush or Razor Blade: A nylon bristle brush or a dedicated scraper removes resin buildup.

- Cleaning Solution: Commercial blade cleaner or a DIY mix of warm water and mild detergent. Avoid harsh acids that can pit the metal.

- Shallow Tray or Tub: A container to soak the blade safely without bending it.

- Rust Inhibitor Spray: Prevent future corrosion once the blade is clean and dry.

- Blade Sharpening Tools: Diamond files or a bench-mounted sharpening system—see the sharpening section below.

Professional workshops may also use a cyclone dust collector to keep airborne particles at bay while cleaning blades and other accessories.

Step-by-Step Cleaning Process

Follow this systematic approach to remove pitch, resin, and sawdust lodged between the teeth.

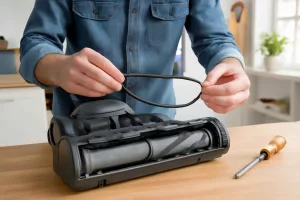

1. Remove and Inspect the Blade

Unplug your saw or remove its battery before loosening the arbor nut. Inspect the blade for missing or chipped teeth. If the damage is extensive, replacement may be more cost-effective than sharpening.

2. Soak the Blade

Place the blade in a tray and pour in enough cleaning solution to cover its teeth and body. Let it soak for 15–30 minutes. This softens resin for easier removal. Keep the blade horizontal to prevent warping.

3. Scrub Away Buildup

Wearing gloves, use a nylon brush or scraper to dislodge pitch. Work along the rotation direction to avoid bending the teeth. Pay special attention to the gullet—the space between teeth where material accumulates.

4. Rinse and Dry Thoroughly

Rinse the blade under running water or wipe it down with a damp cloth. Immediately dry with a clean rag to prevent surface rust. For extra protection, apply a light coat of rust inhibitor spray.

Sharpening Your Circular Saw Blades

Regular sharpening restores the blade’s original geometry and ensures precise cuts. Choose from two common methods:

Hand Filing with Diamond Files

Secure the blade in a flat vise or blade clamp. Use a fine diamond file to touch up each tooth’s bevel, following the manufacturer’s angle (typically 15°–20°). Make even, single-stroke passes without applying excessive downward force.

Bench-Mounted Sharpening Systems

Commercial sharpening jigs hold the blade at the correct angle and advance each tooth against a grinding wheel or diamond disk. This method offers consistent results for busy workshops.

Once sharpened, balance the blade by spinning it on the arbor—if it wobbles, remove a small amount of metal from the heavy side. You can learn more about accurate blade alignment when you calibrate and tune your table saw for precision cuts.

Rust Prevention and Storage Tips

Post-cleaning care is just as important as cleaning itself. Moisture and acids in pitch can corrode your blades if left unchecked.

Apply Protective Coating

After drying, coat the blade lightly with a rust inhibitor or paste wax. Wipe off excess wax with a paper towel so the blade remains clean when reinstalled.

Safe Storage Solutions

Store blades individually in a blade case or hang them on a wall-mounted rack. This prevents contact with other tools and reduces the chance of chipped teeth. For long-term storage in humid environments, consider climate-controlled cabinets or desiccant packs.

For outdoor workshop gear, follow similar principles to winterize your gas pressure washer—protect metal surfaces and store in a dry area.

Troubleshooting Common Blade Issues

Even with routine care, you may encounter cutting problems. Here’s how to diagnose and fix them:

- Burn Marks on Wood: Typically caused by dull teeth or incorrect feed rate. Clean and sharpen the blade, and feed material steadily without forcing it.

- Blades Overheating: Caused by pitch buildup or a fence that’s too close. Clear debris and adjust the fence gap to prevent binding.

- Excessive Vibration: Check blade balance and teeth uniformity. Replace the blade if any teeth are uneven or bent.

- Kickback Incidents: Often due to resin buildup or a clogged gullet. Perform a full cleaning and ensure proper blade alignment.

Conclusion

Consistent circular saw blade maintenance maximizes cutting performance, extends blade life, and enhances workshop safety. By following this guide—cleaning, sharpening, rust prevention, and troubleshooting—you’ll experience smoother cuts and fewer tool-related headaches. Equip yourself with a quality circular saw blade sharpener and protective gear, and integrate maintenance into your regular workflow. For broader tool care strategies, explore tips on how to extend the life of power tool batteries and ensure every tool in your shop stays in peak condition.